Steel Industry

Vega’s domain expertise in Steel Industry is result of providing solution for more than two decades to the industry

From isolated automation to connected digitalization

Embrace Digitalization. Progressively Connected. Modular Approach.

Steel manufacturing industry, especially the secondary steel industry, has undergone its share of rapid changes. Processes made more connected, continuous.

There is a push for more productivity and efficiency. And there is a push for better inter-process coordination.

Steel manufacturers need to go beyond isolated automation to embrace new paradigms. They need to embrace Digitalization for areas inside and outside the organization’s boundaries.

Progressively become more connected – from Enterprise Resource Planning to a more Connected Resource Planning. Take the Modular Implementation approach – prove the benefits and then take the next step, while balancing speed.

Steel manufacturers need to approach this by enhancing the way they run operations

Automate consolidation into MIS / Dashboards of manually collected process data

Connect standard Operations Management areas with Business Management along with feed into process data consolidation

Deploy Extended Operations Management – Material & Genealogy tracking, Intelligent Asset Management, Proactive / Predictive- Maintenance Management, …

Start bringing in Industry 4.0 solutions

CRP® – Embark upon your Industry 4.0 roadmap

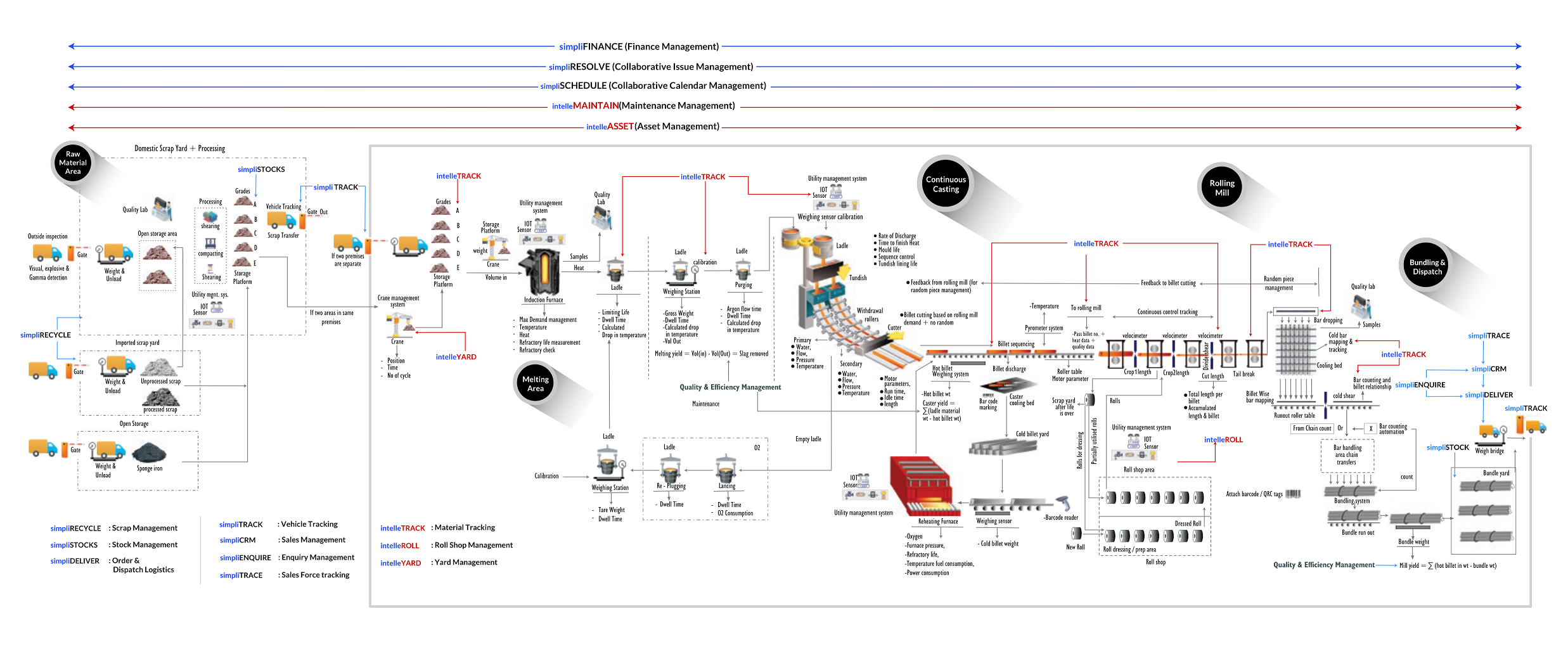

When applied to Steel Industry, CRP® helps to incrementally digitalize the management of operations in raw material/scrap receipt, melting, casting, rolling, bundling, and shipment operations.

Helps build a solid foundation for driving Industry 4.0 initiatives, drive analytics, drive lean practices, drive cost planning efficiencies, and drive a reduction in production waste.

simpliWORKSTM – Digitalize your business operations

The suite, implemented at some of Vega’s long steel manufacturing customers have delivered concrete business benefits.

After implementation our customers have, for example, experienced upto 80% increase in daily dispatch volumes and upto 60% reduction in cost of dispatch operations.

The suite has helped them to take a fully integrated approach to Customer Management, Order Management, Raw material (Sponge Iron, Scrap and Billets) Management, Stock Management, Dispatch Management, and Financials.